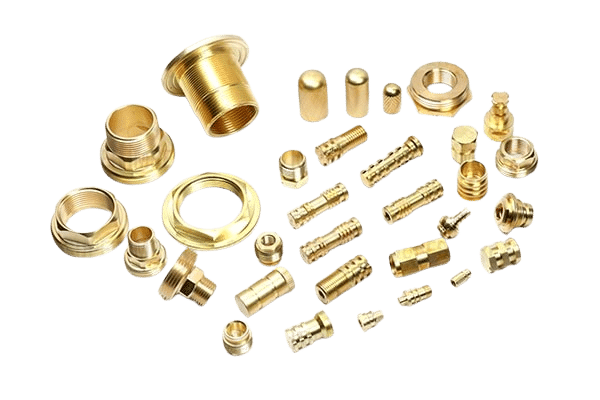

In the world of industrial production, brass parts are critical to a big variety of packages, from automobile additives to plumbing systems. This flexible and durable alloy, composed mainly of copper and zinc, continues to be a cross-to fabric for producing components that require energy, corrosion resistance, and conductivity. As industries develop and demand for excessive-performance components rises, the function of brass parts becomes even greater.

Why Brass? The Choice Metal for Precise Parts

Brass is a unique alloy, combining the pleasant features of copper and zinc, hence making it very suitable for production. Here is why.

- Durability: Very resistant to corrosion, especially in wet or chemically competitive conditions, makes brass comparatively suitable for plumbing fixtures, motor vehicle parts, marine equipment, etc., that must be mindful of rust prevention.

- Malleability: Since brass is flexible, it is more problematic to shape into intricate forms; due to this, there arises a requirement for precision additives such as electric connectors, gearings, and fittings.

- Electrical Conductivity: Though it exposes particular electric conductivity, brass further readily accommodates manufacturing electrical switches, terminals, and connectors.

- Aesthetic Appeal: Brass is similarly prized for its appealing gold-like look, as a consequence of its widespread usage in many ornament quantities, cash, and jewellery.

Key Industries Utilizing Brass Parts

Brass parts assume a critical role in many industries, each possessing individual particular necessities:

1. Automotive Industry

Brass is prominently applied for production additives such as valves, connectors, fittings, and engine parts. Its electricity and resistance to wear make it first-class for automobile structures that require high overall performance below excessive conditions.

2.Customization and Tailored Solutions

Understanding that every enterprise has particular desires, Empire Alloys offers custom-designed answers for their customers. Whether it’s growing a specialized issue for particular software or adjusting the cloth composition to meet unique requirements, Empire Alloys works closely with its customers to ensure they get exactly what they need.

3.Strict Quality Control

At Empire Alloys, high quality is a top priority. Every brass part undergoes a rigorous inspection system to make certain it meets global standards. Using advanced quality manage structures, together with X-ray inspections and ultrasonic testing, the company guarantees that each component is loose from defects and plays as predicted in its supposed utility.

4.Sustainable Practices

Empire Alloys is devoted to sustainability and minimizing environmental impact. The company follows eco-friendly practices, together with recycling brass scrap, using strength-green machinery, and lowering waste in the production system.

5.Global Reach

With its strong manufacturing talents and adherence to global standards, Empire Alloys resources brass parts to diverse industries across the world, from automobile giants to electronic producers. Their worldwide attain guarantees that irrespective of where you are, you may depend upon Empire Alloys for the highest-quality brass additives.

Empire Alloys Pvt. Ltd.: Leading the Way in Brass Parts Manufacturing

Empire Alloys Pvt. Ltd., positioned in Jamnagar, Gujarat, has set up itself as a leader inside the manufacturing of super brass parts for industries across the globe. Known for its commitment to innovation, precision, and niceness, the enterprise employer has garnered robust recognition within the brass production enterprise.

How Empire Alloys Stands Out

Empire Alloys has been at the forefront of brass elements production, serving lots of sectors with its modern-day production techniques. Here’s what makes Empire Alloys a depended-on call in the industry:

1. Advanced Manufacturing Techniques

Empire Alloys utilizes contemporary technologies, which include CNC machining and advanced casting strategies, to supply brass parts that meet the best requirements of precision. These technologies permit steady noise and the ability to manufacture complicated, high-performance additives.

2. Customization and Tailored Solutions

Understanding that each industry has specific desires, Empire Alloys gives customized answers for their customers. Whether it’s developing a specialized element for a selected application or adjusting the cloth composition to fulfil precise requirements, Empire Alloys works carefully with its customers to ensure they get precisely what they want.

3. Strict Quality Control

At Empire Alloys, the best is a top priority. Every brass part undergoes a rigorous inspection technique to ensure it meets global standards. Using advanced great control structures, together with X-ray inspections and ultrasonic checking out, the corporation ensures that each component is loose from defects and plays as anticipated in its intended utility.

4. Sustainable Practices

Empire Alloys is dedicated to sustainability and minimizing environmental impact. The organization follows eco-friendly practices, which encompass recycling brass scrap, using energy-green equipment, and lowering waste inside the production method.

5. Global Reach

With its sturdy manufacturing skills and adherence to worldwide requirements, Empire Alloys elements brass components to diverse industries the world over, from car giants to electronic manufacturers. Their global reach ensures that regardless of where you are, you may depend on Empire Alloys for the best, nice brass components.

The Future of Brass Parts in Manufacturing

As industries continue to evolve, the demand for brass parts is predicted to develop even further. Empire Alloys Pvt. Ltd. is poised to keep the main price in producing excessive overall performance brass additives that meet the ever-converting needs of the market. By embracing technological improvements and staying ahead of industry trends, Empire Alloys will continue to innovate and deliver solutions that power the destiny of manufacturing.